The Environment Is At The Heart Of Everything We Do.

With over 35 years’ experience in the skip hire industry, we have seen it all! From domestic customers renovating a house, to commercial customers completing a large scale site clearance, our range of skip hire options is available to everyone. Whilst we always put our customers needs first and pride ourselves on our reliability and value for money, our position in the waste industry is central to our business.

For us, “The environment is at the heart of everything we do” is not just a simple tagline, it defines our business. At Alan’s Skip Hire, we constantly invest heavily in our staff and fleet to ensure we are always the leading skip hire firm across our service areas.

Our Ongoing Commitment To Recycling

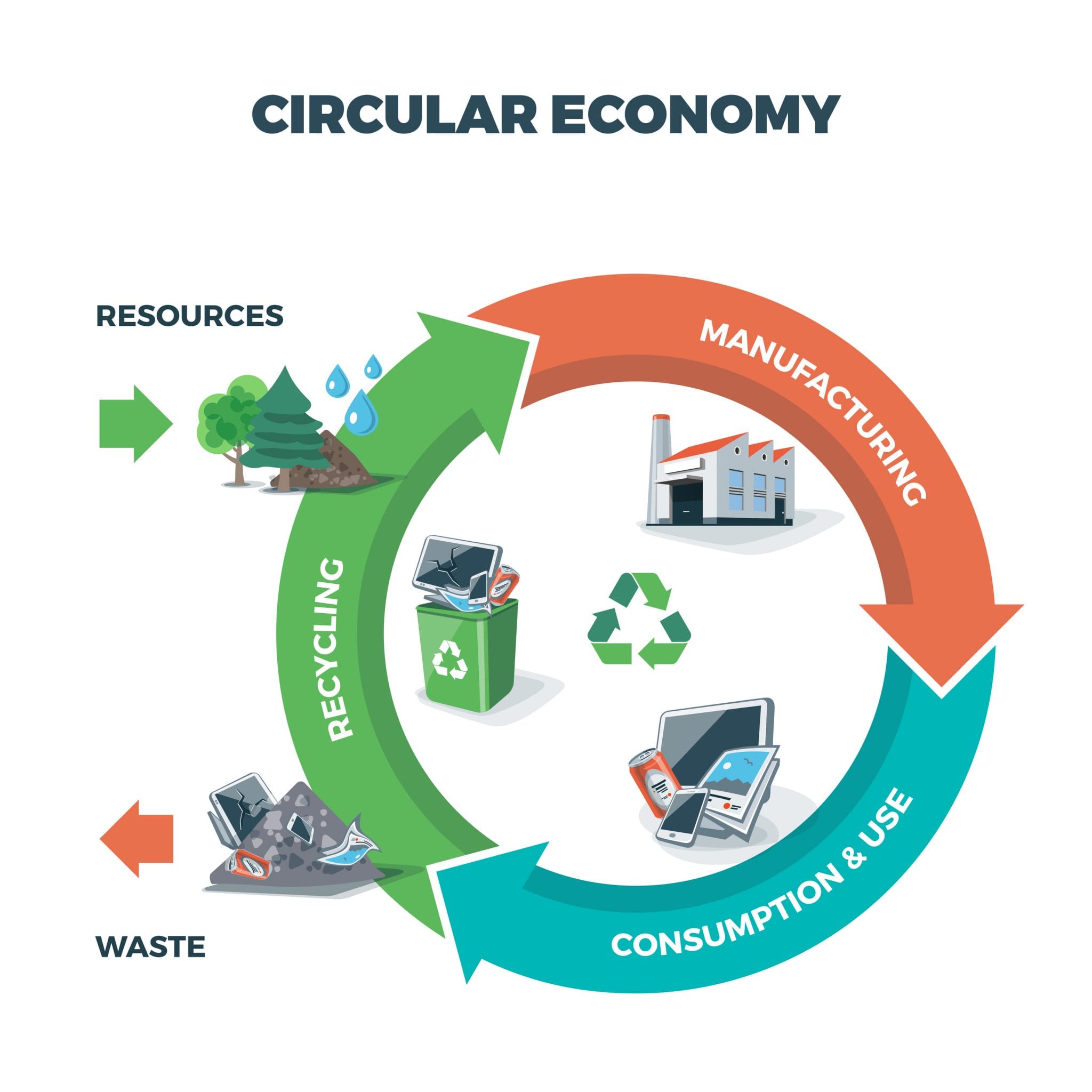

Here at Alan’s Skip Hire, we have a heavy emphasis on resource recovery and the circular economy – in which we keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life.

Our Materials Recycling Facility (MRF) is equipped to allow our team of highly trained operatives to categorise the materials and identify the potential for reuse and recycling. Resources such as wood, metal, cardboard, plastic, green waste, plasterboard, soil and stone is all segregated, bulked and transported to secondary sites for processing, therefore ensuring maximum diversion from landfill and helping our customers to reduce their carbon footprint.

The MRF works by the following process:

- Collected waste materials are loading into a trommel (a mechanical screening machine used to separate materials)

- The finer particles (trommel fines) fall onto a small conveyor

- Magnets are used to separate out metal material for recycling

- The remaining larger materials are fed along a conveyor system and the different material streams are segregated

- The segregated materials are then bulked up, ready to be recycled at secondary sites

- The non-recyclable materials are then used to create refuse derived fuel to create energy and heat within the UK

Our secondary process allows us to further segregate the ‘trommel fines’ for recycling. This process uses a series of conveyors, magnets and wind sifters to create four distinct material streams for recycling and recovery, which traditional operators would send to landfill; soil, stone, metal and a light fraction containing paper and card.

As an ISO 14001:2015 company, our MRF is powered by our own solar panels, further enhancing our environmental ethos. Our PAS 402 Green Compass certificate serves to assure our customers that we report our data accurately. Our OHSAS 18001 certification ensures that our staff are trained and qualified to operate our MRF safely, whilst we employ experienced managers to oversee the day to day operation of the site.

Our customers are invited to contact us for a site visit where our team will talk you through the process we use. You can contact us directly at compliance@ashgroupltd.co.uk